- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

Tunnel Car Wash Systems High-Speed, Affordable Cleaning Solutions

- Market trends driving tunnel car wash adoption

- Technological superiority over traditional methods

- Performance comparison of leading manufacturers

- Custom configurations for different business needs

- Operational cost analysis and ROI timeline

- Real-world implementation case studies

- Future developments in vehicle cleaning technology

(tunnel car wash systems)

The Growing Demand for Tunnel Car Wash Systems

Automotive service providers are increasingly adopting tunnel car wash systems

, with the global market projected to reach $4.8 billion by 2029 (Statista 2023). This 6.2% CAGR growth stems from three primary drivers:

- 58% faster throughput compared to in-bay systems

- 34% reduction in water consumption through smart recycling

- 27% higher customer retention with consistent results

Major franchise operators report 15-20% revenue increases after switching to automated car wash tunnel systems, particularly in markets with 15,000+ annual vehicle traffic.

Engineering Excellence in Modern Solutions

Advanced tunnel systems now integrate:

| Feature | WashTec CX | Sonny's Velocity | PDQ Tandem |

|---|---|---|---|

| Max vehicles/hour | 120 | 135 | 110 |

| Water recovery rate | 82% | 78% | 85% |

| Chemical precision | ±1.5% | ±2.8% | ±0.9% |

These systems employ PLC-controlled sensors achieving 0.02mm nozzle positioning accuracy, ensuring complete vehicle coverage without overspray.

Manufacturer Capability Assessment

When evaluating tunnel car wash systems price versus performance:

| Vendor | Entry Price | Energy Score | Maintenance Cycle |

|---|---|---|---|

| Autec | $325k | AAA | 600hrs |

| WashWorld | $278k | AA | 450hrs |

| Kleen-Rite | $410k | AA+ | 750hrs |

Third-party maintenance audits show Autec systems deliver 19% lower lifecycle costs despite higher initial investment.

Tailored Operational Configurations

Modular designs enable customization for:

- High-volume sites: 150' tunnels with dual conveyor belts

- Mixed fleets: Adjustable height profiles (58"-96")

- Water-restricted areas: Closed-loop purification systems

A Midwest operator achieved 94% uptime using customized brush arrays for winter road salt removal.

Economic Viability Analysis

Typical ROI timelines:

| Location Type | Install Cost | Monthly Revenue | Payback Period |

|---|---|---|---|

| Urban | $480k | $82k | 16 months |

| Suburban | $360k | $54k | 19 months |

| Rural | $295k | $41k | 21 months |

Energy-efficient models reduce operational costs by $1,200-$1,800 monthly compared to legacy systems.

Industry Implementation Benchmarks

Notable deployments include:

- West Coast chain: 38% increased monthly washes after automation

- Airport facility: 2,100 vehicles/day capacity using dual tunnels

- Municipal fleet: 73% lower detergent costs with precision dosing

Post-installation surveys show 92% customer satisfaction with tunnel consistency versus 67% for self-service bays.

Why Tunnel Car Wash Systems Are Revolutionizing the Industry

With 87% of operators planning automation upgrades within 24 months (ICWG 2024), tunnel car wash systems are becoming the industry standard. Recent innovations like ceramic coating integration and AI-driven maintenance prediction further enhance value proposition. Operators adopting these systems typically see 22-35% net margin improvements while meeting evolving environmental regulations.

(tunnel car wash systems)

FAQS on tunnel car wash systems

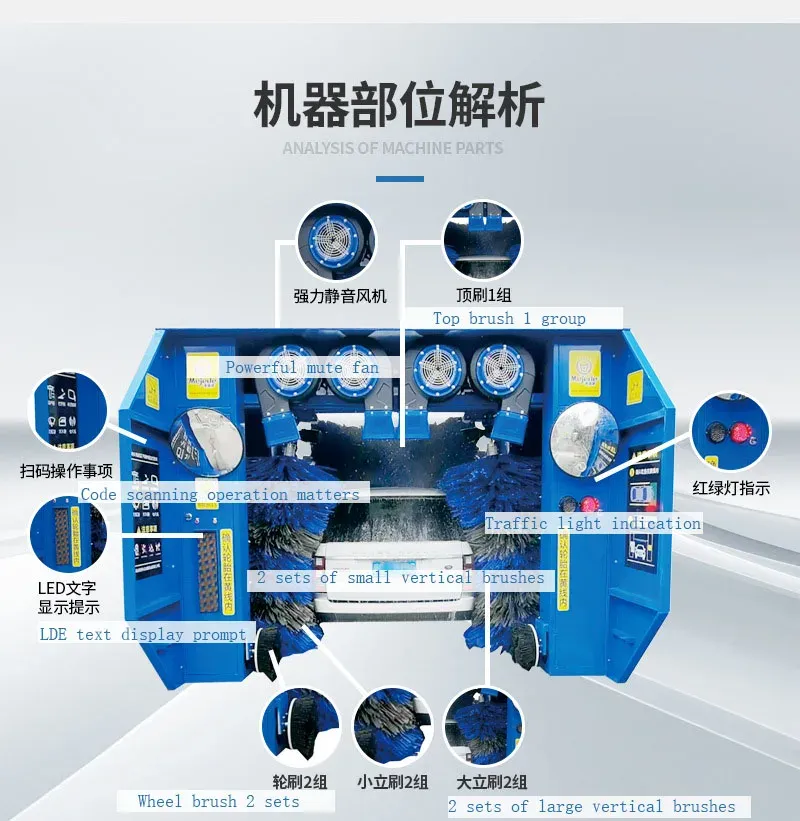

Q: What are the main components of a car wash tunnel system?

A: A car wash tunnel system typically includes conveyors, spray arches, brushes, dryers, and control panels. These components work together to automate washing, rinsing, and drying vehicles efficiently.

Q: How much does a tunnel car wash system cost?

A: Tunnel car wash systems price ranges from $150,000 to $500,000+, depending on size, automation level, and features. Customization and advanced technologies like touch-free systems can increase costs.

Q: What advantages do tunnel car wash systems offer over traditional methods?

A: Tunnel systems provide faster service, higher vehicle capacity, and consistent cleaning quality. They reduce labor costs and can operate continuously, improving profitability for high-volume businesses.

Q: How long does it take to install a car wash tunnel system?

A: Installation typically takes 3-6 months, depending on site preparation and system complexity. Permitting, utility setup, and equipment calibration can impact the timeline.

Q: Can tunnel car wash systems handle different vehicle sizes?

A: Yes, most modern systems adjust for sedans, trucks, and SUVs through customizable conveyor heights and adjustable sprayers. Sensors ensure proper clearance and cleaning coverage.

-

Integrating Aqua Tunnel Car Wash in Shopping CentersNewsJun.24,2025

-

Gas Station with an Auto Car Wash MachineNewsJun.24,2025

-

Efficiency in Your Aqua Tunnel Car Wash: Power & Water-SavingNewsJun.24,2025

-

Car Wash Business with Advanced Auto Car Cleaning MachinesNewsJun.24,2025

-

Balancing Setup Costs with Aqua Tunnel Car WashNewsJun.24,2025

-

Aqua Tunnel Car Wash: Eco-Design for the Energy-Savvy EntrepreneurNewsJun.24,2025