- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

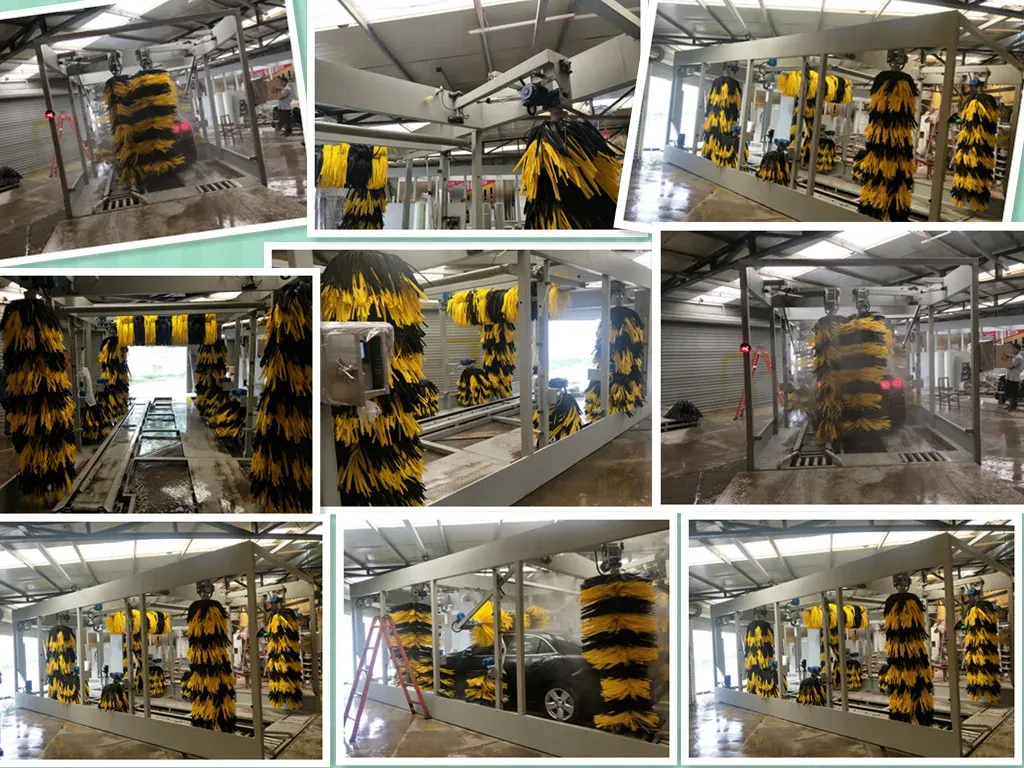

automobile component washing machine

The Importance of Automobile Component Washing Machines in Modern Manufacturing

In the dynamic world of automobile manufacturing, precision and cleanliness are paramount. One crucial piece of equipment that plays a vital role in this industry is the automobile component washing machine. These machines are designed to effectively clean various automobile parts, ensuring that they meet the stringent standards required for quality and performance.

Understanding Automobile Component Washing Machines

Automobile component washing machines are specialized devices that use various cleaning methods to remove contaminants from vehicle parts. This includes grease, oil, dirt, and other debris that can accumulate during manufacturing or maintenance processes. The machines are equipped with advanced technologies such as ultrasonic cleaning, high-pressure jets, and chemical rinses to ensure thorough cleaning.

Ultrasonic Cleaning This method involves using high-frequency sound waves to create cavitation bubbles in a cleaning solution. When these bubbles collapse, they produce shock waves that dislodge contaminants from the surface of the parts. This is particularly effective for cleaning intricate components with complex geometries.

High-Pressure Washing High-pressure washers can remove heavy debris and contaminants quickly. They work by forcing water or cleaning solutions through a nozzle at high speeds, allowing the force to break down stubborn dirt and grease. This method is commonly used for larger parts and assemblies.

Chemical Cleaning Some washing machines utilize specialized cleaning solutions that are designed to break down oils and other contaminants. These chemical processes can be more efficient and effective for specific types of contaminants, making them a valuable option in component washing.

Benefits of Using Automobile Component Washing Machines

1. Improved Quality Control Clean components are essential for ensuring the overall reliability and performance of vehicles. By using washing machines, manufacturers can ensure that every part is free of contaminants, which can lead to defects and failures.

2. Enhanced Production Efficiency Automating the cleaning process allows manufacturers to streamline their operations. Instead of relying on manual cleaning, which can be time-consuming and inconsistent, washing machines provide a reliable solution that can handle large volumes of parts quickly.

3. Reduced Maintenance Costs Regular and thorough cleaning of components can lead to a longer lifespan for automotive parts. By preventing the buildup of dirt and grime, manufacturers can reduce wear and tear, leading to lower maintenance costs in the long run.

automobile component washing machine

4. Environmental Compliance With increasing regulations on waste and emissions, manufacturers must ensure that their cleaning processes are environmentally friendly. Modern automobile component washing machines are designed to minimize waste and use eco-friendly cleaning agents, helping companies maintain compliance with environmental standards.

Choosing the Right Washing Machine

When selecting an automobile component washing machine, several factors should be considered

- Type of Components Different components may require different cleaning methodologies. Understanding the part's material and complexity will help in selecting the most suitable machine.

- Volume of Parts The scale of production will influence the size and capacity of the washing machine. Manufacturers must choose a machine that fits their production needs while maintaining efficiency.

- Cleaning Method Depending on the type of contaminants and components, manufacturers should evaluate which cleaning method (ultrasonic, high-pressure, or chemical) will be most effective.

- Regulatory Requirements It's essential to choose a washing system that complies with industry standards and environmental regulations.

Future Trends in Automobile Component Washing

As the automotive industry continues to evolve, so do the technologies used in component washing. The integration of robotics and automation in these machines promises to further enhance efficiency and precision. Additionally, the development of more environmentally friendly cleaning agents and systems underscores the industry's commitment to sustainability.

In conclusion, automobile component washing machines are a cornerstone of quality assurance in manufacturing. By ensuring that every part is cleaned to perfection, manufacturers can enhance production efficiency, improve vehicle reliability, and meet environmental standards. As technologies advance, these machines will only become more integral to the future of automobile production. Investing in the right component washing equipment will undoubtedly pay off, fostering a cleaner, more efficient, and sustainable manufacturing process.

-

Integrating Aqua Tunnel Car Wash in Shopping CentersNewsJun.24,2025

-

Gas Station with an Auto Car Wash MachineNewsJun.24,2025

-

Efficiency in Your Aqua Tunnel Car Wash: Power & Water-SavingNewsJun.24,2025

-

Car Wash Business with Advanced Auto Car Cleaning MachinesNewsJun.24,2025

-

Balancing Setup Costs with Aqua Tunnel Car WashNewsJun.24,2025

-

Aqua Tunnel Car Wash: Eco-Design for the Energy-Savvy EntrepreneurNewsJun.24,2025