automated car wash business

One of the primary advantages of air pressure car washers is their efficiency. Traditional water-based washing can be time-consuming and often requires additional scrubbing or rinsing. In contrast, air pressure washers quickly blast away dirt with minimal effort. The force of the high-pressure air can reach nooks and crannies that are otherwise difficult to clean, ensuring a thorough cleanse without the need for extensive manual labor.

Express car wash systems are designed to optimize the washing process, ensuring that vehicles are cleaned thoroughly in a fraction of the time it used to take. Traditional car washes often involve multiple steps and can take anywhere from 20 minutes to an hour. In contrast, express car wash equipment streamlines this process, allowing cars to be cleaned in as little as 3 to 5 minutes. This is made possible through sophisticated machinery that employs advanced techniques, such as high-pressure water jets and automated brushes, to deliver exceptional results quickly.

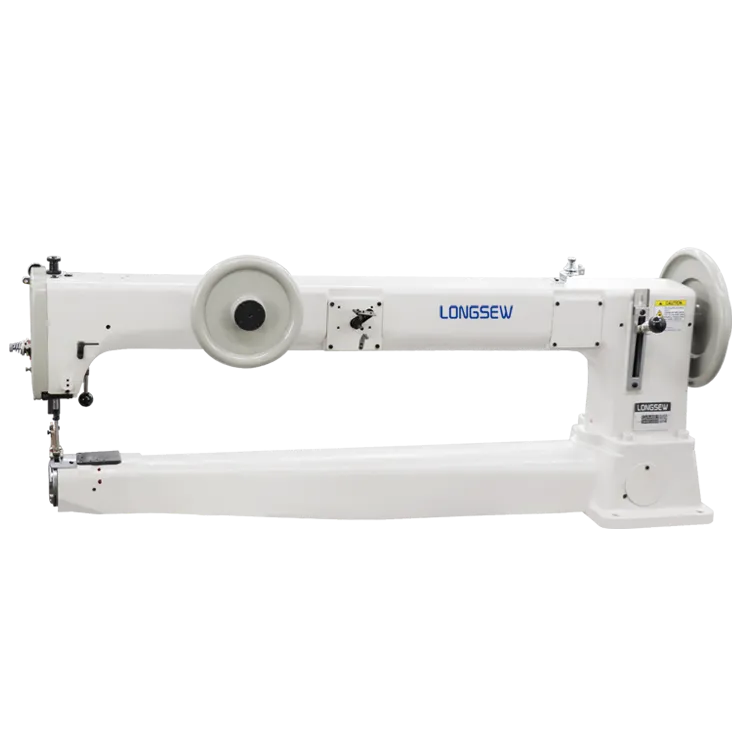

industrial overlock machine. With its high-speed operation and automatic thread trimming, this machine can quickly and easily finish seams and edges, saving time and labor in the production process. Whether working in a small-scale sewing business or a large-scale garment factory, an industrial overlock machine is an essential tool for improving productivity and achieving consistent and professional results.

industrial overlock machine. With its high-speed operation and automatic thread trimming, this machine can quickly and easily finish seams and edges, saving time and labor in the production process. Whether working in a small-scale sewing business or a large-scale garment factory, an industrial overlock machine is an essential tool for improving productivity and achieving consistent and professional results.The construction of these machines typically includes a robust frame, which supports the sewing head and allows for the rapid movement of the needle

. Advanced models are often equipped with features such as automatic thread cutting, needle positioning, and programmable stitch patterns, facilitating greater ease of use and enhancing operational efficiency.While industrial sewing machines are essential for constructing garments, overlockers play a crucial role in finishing and securing the edges of fabrics. These specialized machines sew over the edge of the fabric, preventing fraying and giving garments a professional look. Overlockers can trim excess fabric while simultaneously stitching, making them incredibly efficient for tasks like hemming and seaming.

industrial sewing machine and overlocker