car wash scrubbers

Öncelikle, otomatik araç yıkama sistemlerinin türleri arasında büyük bir maliyet farklılığı vardır. Basit bir el ile yıkama sistemine göre daha gelişmiş bir oto yıkama tesisi kurmak, çok daha yüksek başlangıç maliyetleri gerektirir. Genellikle, 10.000 Dolar ile 150.000 Dolar arasında değişen maliyetler, tesisin büyüklüğüne, kullanılan ekipmanın türüne ve otomatik sistemin özelliklerine bağlı olarak değişir. Bu sistemi kurmayı planlayan girişimcilerin, ihtiyaçlarına uygun en iyi çözümü bulmak için kapsamlı bir piyasa araştırması yapmaları gerekmektedir.

automatic car wash systems cost

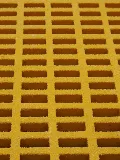

In addition to its lightweight nature, FRP mesh grating boasts impressive durability and longevity. It is engineered to withstand harsh environmental conditions, including exposure to chemicals, UV radiation, and extreme temperatures. This makes it particularly useful in industries such as wastewater treatment, petrochemicals, and food processing, where materials are frequently subjected to corrosive substances and rigorous cleaning processes. Unlike metal gratings that may corrode over time, FRP maintains its structural integrity, reducing the need for frequent replacements and maintenance.

frp mesh grating

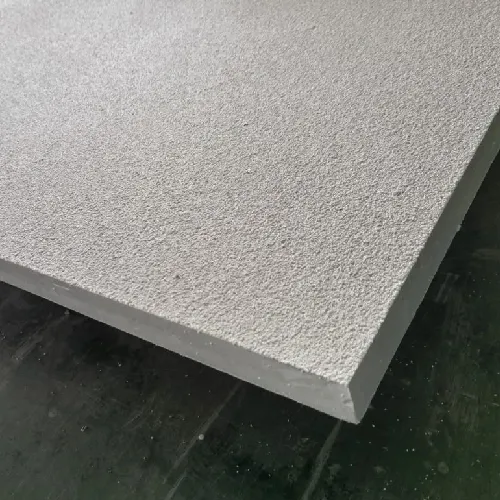

Another significant benefit of galvanized storage tanks is their low maintenance requirements

. The zinc coating not only prevents rust but also reduces the frequency of needed inspections and repairs, which can be both time-intensive and costly. For businesses operating on tight margins or with limited resources, the longevity and low upkeep of these tanks can lead to significant cost savings over time.galvanized storage tank

Another benefit of Balmoral sectional tanks is their ease of installation. Because the tanks are assembled on-site using prefabricated panels, they can be put together quickly and with minimal disruption to the surrounding area. This makes them an ideal choice for projects that have tight deadlines or limited access to the site.

balmoral sectional tanks

There are several types of machine guards, each designed for specific types of machinery and processes. Fixed guards are permanent and provide a solid barrier against moving parts. Adjustable guards can be modified for different tasks and machinery setups. Interlocking guards are designed to be connected to the machine’s operation; they ensure that the machine cannot operate if the guard is not properly positioned. Moreover, electronic safety systems exist, which use sensors. These systems can detect the presence of a worker in a hazardous area and immediately shut down the machinery to prevent an accident.

machine guarding systems