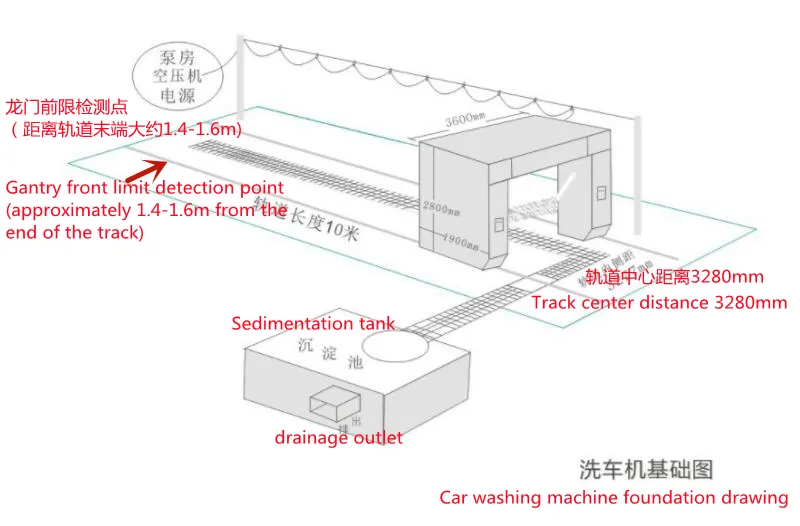

car bike washing station

One of the most appealing aspects of driven car wash machines is their user-friendliness. Car owners can simply drive their vehicles into the wash bay, select their preferred wash cycle, and let the machine do the rest. With automated processes, customers can enjoy a relaxing experience without the need for manual labor. Many establishments also offer features such as an exterior wax finish, undercarriage wash, and even a drying cycle that uses high-powered blowers to ensure that no streaks are left behind.

drivn car wash machine

One of the most appealing aspects of specialty car wash systems is their customization options

. Car owners can choose from an array of services tailored to their specific needs, whether it's a quick rinse, an exterior wash, or an in-depth detailing service. Some systems even offer specialized treatments, such as ceramic coating or paint protection, to help maintain the vehicle's appearance and preserve its value over time.specialty car wash systems

One of the standout features of contemporary automated car wash equipment is its integration with smart technology. Many modern systems are equipped with sensors and cameras that enhance the cleaning process. These sensors can detect dirt levels and adjust water pressure accordingly, ensuring that each car receives a customized wash. Additionally, some systems utilize computer algorithms to optimize the sequence of cleaning actions, resulting in reduced water and energy consumption.

automated car wash equipment

Durability is a hallmark of square wire mesh fencing. Generally constructed from high-quality steel, these fences are resistant to rust and corrosion, especially when galvanized. This makes them suitable for long-term outdoor use, even in harsh weather conditions. Furthermore, they require minimal maintenance, as occasional inspections for wear and proper tightening of knots or connections are typically all that’s needed to retain their structural integrity.

square wire mesh fence

black steel nail factory. Their strength and durability make them an ideal choice for these types of projects, as they can hold up under the weight and pressure of heavy materials. In addition, the black coating helps to prevent rust and corrosion, ensuring that the nails will last for years to come.

Tube fiberglass is also highly versatile and can be customized to suit specific project requirements. It can be easily molded into different shapes and sizes, making it suitable for a wide range of applications. Whether it's used for structural support, insulation, or as a protective covering, tube fiberglass offers flexibility and adaptability to meet the needs of various industries.

tube fiberglass

In addition to its corrosion resistance, frp tray is also lightweight and easy to install, making it a cost-effective solution for many industrial applications

. The trays can be easily cut and modified on-site to fit specific requirements, reducing the need for custom fabrication and saving time and money during installation. The lightweight nature of the material also means that frp trays are easy to handle and transport, further simplifying the installation process.frp tray