vacuums at car wash

The efficiency of commercial car shampooers is unmatched. With their ability to deliver high-pressure water jets, these machines can penetrate deep into fabric fibers, loosening dirt particles that are otherwise difficult to remove. After cleaning, they utilize strong suction capabilities to extract excess water, ensuring that surfaces dry quickly and preventing mold or mildew growth. For car detailing businesses, this means faster turnaround times and satisfied customers.

commercial car shampooer

A wash rack is a designated area where vehicles, equipment, and machinery are cleaned. Traditionally, these operations consume significant amounts of water, contributing to wastage and environmental degradation. Furthermore, the runoff from washing vehicles often contains harmful contaminants like oil, grease, dirt, and chemicals, which can pose a risk to local water sources. The implementation of a wash rack water recycling system addresses these issues by allowing for the efficient purification and reuse of wash water, thus minimizing both water consumption and pollution.

Moreover, building emotional intelligence plays a crucial role in fostering resilience. Understanding and managing one’s emotions, as well as empathizing with the emotions of others, allows for healthier interpersonal relationships and clearer decision-making. Emotionally intelligent individuals are better equipped to handle stress, navigate conflicts, and provide support to others, thus creating a supportive community that bolsters collective resilience.

forge résistant.

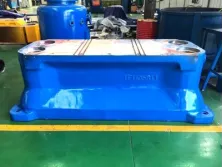

In many cases, gravel pump manufacturers also provide tailored solutions to meet the specific needs of their clients. Customization can include pump size, material compatibility, and additional features such as improved sealing systems and automated controls. By collaborating with clients to understand their unique requirements, manufacturers can deliver high-performing pumps that enhance productivity and minimize downtime.

fabricantes de bombas de grava