car wash machine pressure

Ключевым элементом успеха мобильного детализирования является правильная подготовка оборудования. При выборав мойку под давлением, стоит обратить внимание на наличие различных насадок. Специальные насадки помогают адаптировать поток воды в зависимости от задачи для бережной мойки кузова можно использовать широкую насадку с низким давлением, а для очистки колесных дисков подойдёт узкая насадка с высоким давлением.

pressure washer for mobile car detailing

Once inside, the true magic of the Tunnel of Luv unfolds. The car wash tunnel resembles an amusement park ride, with colorful lights, cheerful music, and mesmerizing soap sprays dancing across the windshield as the vehicle glides through the wash. High-tech sprayers and foam brushes work in unison, ensuring that each car receives a thorough cleaning. The process is not just efficient; it is a visual spectacle, transforming the mundane act of washing a car into a multi-sensory experience.

tunnel of luv car wash

But the benefits do not end there. Upon completing the wash, many drive-through car washes now include vacuum stations that are either integrated into the service or conveniently located in the same lot. This means that as soon as your car emerges from the wash, you can effortlessly transition to vacuuming the interior. The vacuum stations usually come equipped with powerful suction, making it easy to remove dirt, crumbs, and other debris from seats and carpets.

drive through car wash with vacuum

Car maintenance is an essential part of preserving the value and appearance of your vehicle. Among the various methods available for keeping your car clean, a pressure washer system stands out as an efficient and effective choice. Combining high-pressure water jets with specialized cleaning agents, a car wash pressure washer system is designed to tackle dirt, grime, and tough stains that accumulate on your vehicle's surface.

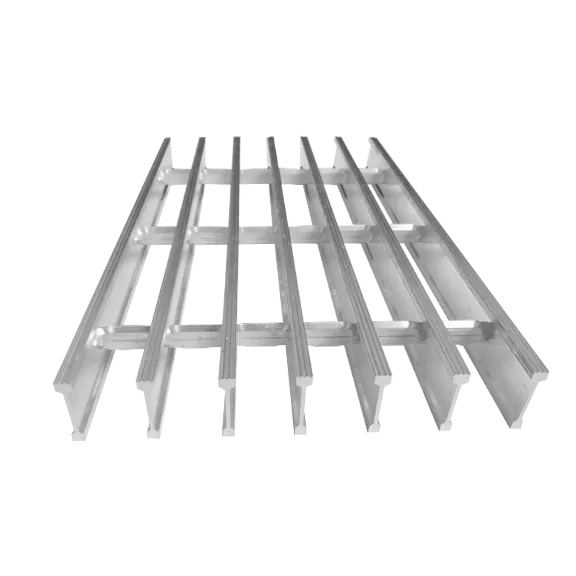

Another advantage of painted steel grating is its easy installation and maintenance. It can be easily cut to size and installed using simple tools, reducing labor costs and project timelines. In cases where repairs or replacements are necessary, painted steel grating can be removed and replaced without extensive damage to the surrounding area. Additionally, regular maintenance typically involves only periodic inspections and touch-ups of the paint, making it a cost-effective choice in the long run.