car wash vacuum

1. Type of Machine High pressure car wash machines come in several types, including electric, gas, and diesel-powered versions. Electric machines are generally more affordable and suitable for home use. However, gas and diesel machines, while pricier, provide increased power and versatility, making them ideal for commercial applications.

In the realm of vehicle customization, detailing trailers has emerged as a significant aspect that combines aesthetics with practicality

. Trailers serve various purposes, from transporting goods to serving as mobile offices or living spaces. Consequently, investing time and effort into detailing can transform a standard trailer into a remarkable one, setting it apart on the road.With increasing awareness of environmental issues, commercial car washers are also adapting to use water and cleaning chemicals more responsibly. Many advanced systems recycle water, reducing waste and ensuring that only a minimal amount is used during each wash. Additionally, eco-friendly cleaning products are becoming the norm, minimizing the impact of chemicals on the environment. This commitment to sustainability not only helps the planet but also attracts environmentally conscious consumers who prefer businesses that take care of their ecological footprint.

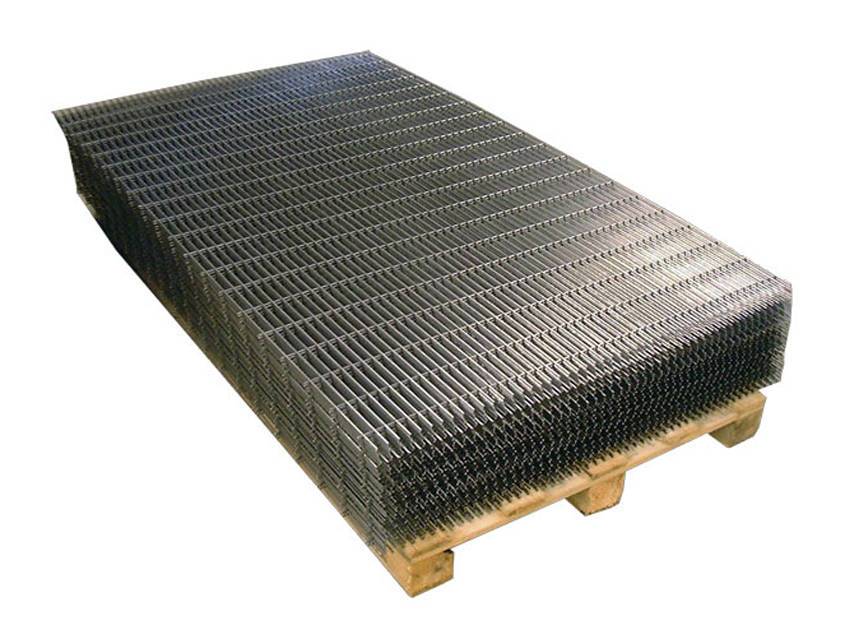

2. Disease Prevention By keeping plants off the soil, wire supports help reduce the risk of soil-borne diseases. Many plants, particularly those prone to rot, can suffer when contact with wet soil is not mitigated. Supports ensure better air circulation and dryness around the base of the plant, creating a healthier growing environment.

wire plant supports

One of the key benefits of L-shaped brick ties is their ability to provide enhanced strength and stability. The design allows for a robust connection between the brick veneer and the supporting structure. By securing the brick to the wall, these ties prevent the veneer from separating or bowing, which can lead to significant structural problems. This is particularly important in regions prone to high winds or seismic activity, where the stability of the brickwork is critically tested.

l shaped brick ties

Round wire springs find applications across a multitude of industries. In the automotive sector, they are essential for shock absorption and contributing to overall vehicle stability. In manufacturing, they are incorporated into assemblies where they support the smooth operation of machinery and equipment. Other sectors like healthcare utilize round wire springs in devices such as hospital beds and medical instruments due to their reliability and customized form factors.