commercial car wash vacuum systems

One of the significant advantages of a rolling car wash service is its ability to cater to various customer needs and preferences

. From basic exterior washes to comprehensive detailing that includes waxing, interior cleaning, and even engine bay cleaning, these mobile services offer a broad spectrum of options. This flexibility ensures that car owners can choose a package that best suits their vehicle’s condition and their budget.rolling car wash

One of the most appealing features of electric high-pressure car washers is their user-friendly operation. Most models are lightweight and portable, allowing car owners to wash their vehicles conveniently at home, without the need to visit a car wash. Additionally, many units come equipped with adjustable nozzles that allow users to switch between different spray patterns, depending on the type of cleaning required. For instance, a wide spray may be ideal for rinsing off soap, while a concentrated jet could effectively blast away stubborn mud or tar.

electric high pressure car washer

For entrepreneurs, investing in a fully automated car wash presents an attractive business opportunity. The initial setup cost can be higher than traditional washing facilities, but the return on investment often justifies the expense. Fully automated car washes require fewer employees, reducing labor costs and streamlining operations. Once established, they can serve a high volume of customers with minimal maintenance, making them a sustainable and profitable endeavor.

fully automated car wash for sale

With increasing awareness of environmental issues, commercial car washers are also adapting to use water and cleaning chemicals more responsibly. Many advanced systems recycle water, reducing waste and ensuring that only a minimal amount is used during each wash. Additionally, eco-friendly cleaning products are becoming the norm, minimizing the impact of chemicals on the environment. This commitment to sustainability not only helps the planet but also attracts environmentally conscious consumers who prefer businesses that take care of their ecological footprint.

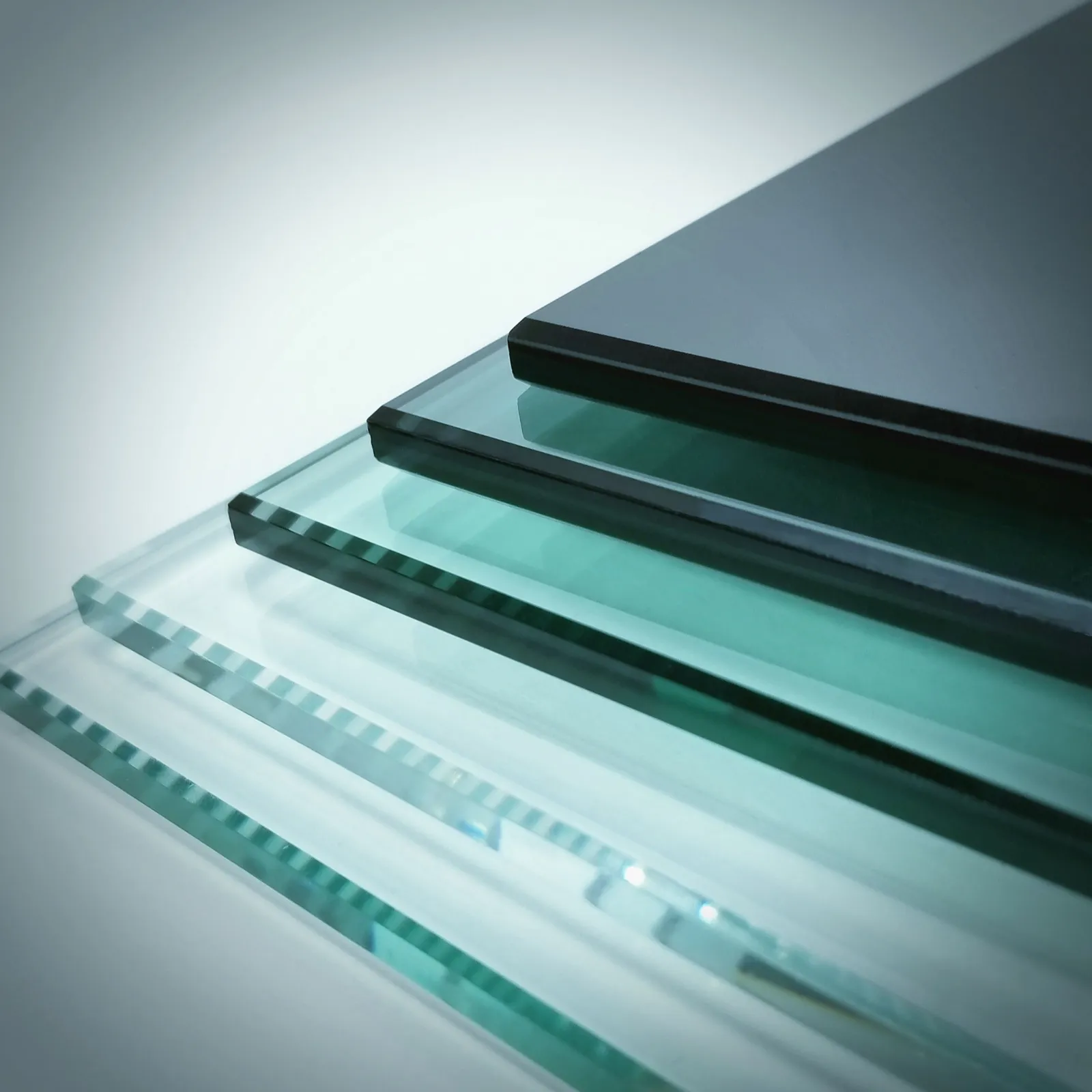

Furthermore, side windows and sunroofs often use laminated glass, which includes a layer of tempered glass sandwiched between sheets of plastic for added protection Furthermore, side windows and sunroofs often use laminated glass, which includes a layer of tempered glass sandwiched between sheets of plastic for added protection

Furthermore, side windows and sunroofs often use laminated glass, which includes a layer of tempered glass sandwiched between sheets of plastic for added protection Furthermore, side windows and sunroofs often use laminated glass, which includes a layer of tempered glass sandwiched between sheets of plastic for added protection thick tempered glass.

thick tempered glass.

satin acid etched glass. A simple wipe with a damp cloth is usually all that is needed to keep satin acid-etched glass looking clean and fresh.

The float glass production process begins with the melting of raw materials, including silica sand, soda ash, and limestone, at high temperatures. This molten mixture is then floated on top of molten tin, allowing the glass to spread evenly and form a continuous sheet. As the glass moves through the annealing lehr—a controlled cooling chamber—it gradually solidifies and is cut into standardized sheet sizes.

float glass sheets