car ac wash

The technology behind automated car wash equipment has improved dramatically over the years. Modern car washes employ a combination of laser guidance systems, soft cloth brushes, high-pressure water jets, and eco-friendly cleaning solutions. This advanced approach not only ensures that vehicles receive a thorough clean but also minimizes the risk of scratches and damage, which can often occur with manual washing methods. Furthermore, these systems are designed to conserve water, making them an environmentally friendly choice for vehicle cleaning.

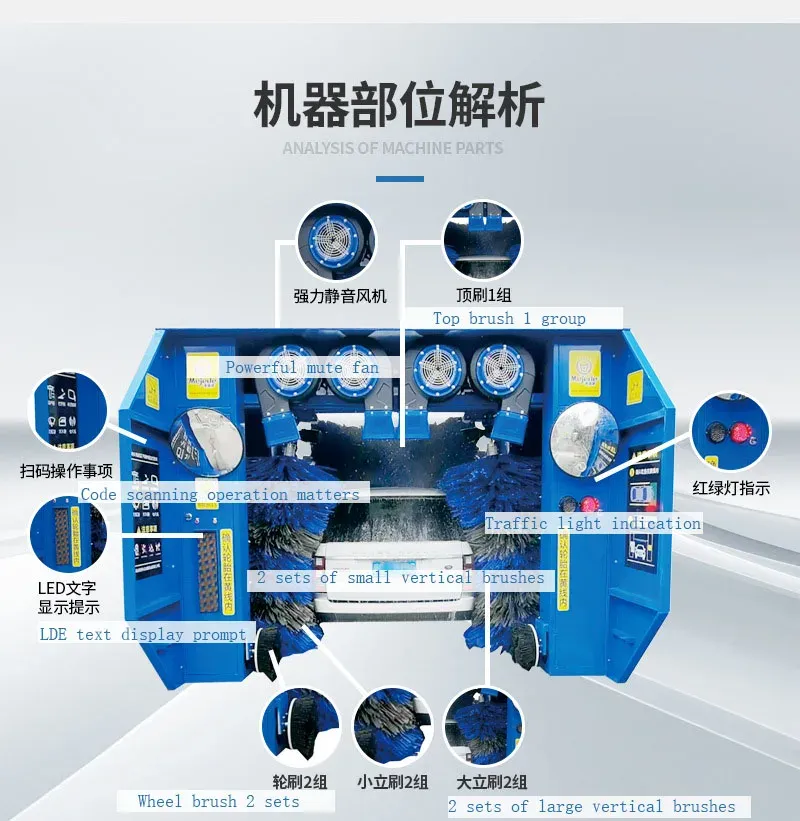

automated car wash equipment

Another important feature is the inclusion of various nozzle types. Most pressure washers come with interchangeable nozzles that allow you to switch between narrow and wide spray patterns. A wide-angle nozzle is perfect for rinsing large surfaces, while a narrow nozzle can help target tough spots. A foam cannon attachment is also a fantastic addition, as it allows you to apply soap evenly and generously over the vehicle surface, enhancing the cleaning process.

good pressure washer for washing cars

Maintaining a car wash operation requires not only top-notch equipment but also prompt and effective repair services to ensure the smooth running of daily operations. Car washing machinery, from automatic systems to pressure washers, is vital in delivering quality service to customers. When these essential tools break down, it can lead to significant downtime and loss of business. Hence, understanding the key aspects of car washer repairing is crucial for any operator.

Moreover, pressure washers are not only powerful but also customizable. Many machines come with adjustable nozzles that allow users to control the intensity of the water pressure, making it easy to switch between different cleaning tasks. For instance, a gentle wash can be ideal for delicate surfaces like paint or glass, while a more aggressive setting may be necessary for more robust areas such as tires or the exterior undercarriage.

pressure washer machine for car

The construction of these machines typically includes a robust frame, which supports the sewing head and allows for the rapid movement of the needle

. Advanced models are often equipped with features such as automatic thread cutting, needle positioning, and programmable stitch patterns, facilitating greater ease of use and enhancing operational efficiency.