Current location:Home > car wash boom for sale >

car wash boom for sale

2025-08-16 06:50

2025-08-16 06:27

2025-08-16 06:22

2025-08-16 06:05

2025-08-16 06:03

2025-08-16 06:00

2025-08-16 04:48

2025-08-16 04:43

2025-08-16 04:39

2025-08-16 04:27

Latest articles

Moreover, advancements in technology have allowed automated car washes to offer high-quality cleaning without manual labor. Utilizing state-of-the-art equipment, these car washes employ soft cloth materials, high-pressure nozzles, and eco-friendly detergents. These smart systems ensure that cars receive a gentle yet thorough cleaning that is both effective and safe for the vehicle’s surfaces. Additionally, many modern automated car washes feature onboard computer systems that adjust water pressure, soap application, and drying times based on the vehicle type—resulting in a customizable experience tailored to each customer’s needs.

automated car wash business

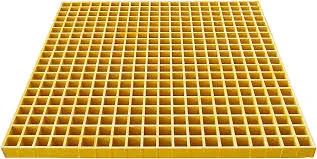

Another benefit of pultruded fiberglass grating is its low maintenance requirements

pultruded fiberglass grating. Unlike metal gratings, which require regular painting and cleaning to prevent corrosion, fiberglass grating is virtually maintenance-free. It is easy to clean with soap and water, and does not require any special coatings or treatments to maintain its integrity.

pultruded fiberglass grating. Unlike metal gratings, which require regular painting and cleaning to prevent corrosion, fiberglass grating is virtually maintenance-free. It is easy to clean with soap and water, and does not require any special coatings or treatments to maintain its integrity.

In addition to the materials used in their construction, vessels and tanks must also be designed with features that ensure the safety and efficiency of their operation vessels and tanks. This includes the use of pressure relief valves, level sensors, and access ports for cleaning and maintenance.

vessels and tanks. This includes the use of pressure relief valves, level sensors, and access ports for cleaning and maintenance.

vessels and tanks. This includes the use of pressure relief valves, level sensors, and access ports for cleaning and maintenance.

vessels and tanks. This includes the use of pressure relief valves, level sensors, and access ports for cleaning and maintenance.It was not until the development of the hydraulic drifter in the 1950s that rock drilling truly entered the modern era drifter for rock drill. This innovative tool used high-pressure hydraulic fluid to power a piston that rotated the drill bit, allowing for much greater penetration rates and precision. The hydraulic drifter quickly became the go-to tool for drilling holes in hard rock, paving the way for many of the major engineering projects of the time.

drifter for rock drill. This innovative tool used high-pressure hydraulic fluid to power a piston that rotated the drill bit, allowing for much greater penetration rates and precision. The hydraulic drifter quickly became the go-to tool for drilling holes in hard rock, paving the way for many of the major engineering projects of the time.

drifter for rock drill. This innovative tool used high-pressure hydraulic fluid to power a piston that rotated the drill bit, allowing for much greater penetration rates and precision. The hydraulic drifter quickly became the go-to tool for drilling holes in hard rock, paving the way for many of the major engineering projects of the time.

drifter for rock drill. This innovative tool used high-pressure hydraulic fluid to power a piston that rotated the drill bit, allowing for much greater penetration rates and precision. The hydraulic drifter quickly became the go-to tool for drilling holes in hard rock, paving the way for many of the major engineering projects of the time.