Once the equipment is installed, the work of car wash equipment installers is not over

. They typically conduct tests to ensure that everything is functioning correctly. This includes checking the pressure in washing systems, testing spray patterns, and verifying that all electronic components are operational. Furthermore, installers often provide training to the car wash staff on how to operate the equipment, ensuring that employees understand the operations and safety protocols associated with the machines.clean machine detailing

One of the most significant advantages of high pressure water jet systems is their versatility. They can effectively clean various surfaces, including painted exteriors, wheels, and undercarriages. This adaptability allows car wash businesses to cater to a wide variety of customer needs, from basic washes to detailed cleaning jobs. Additionally, the quick drying time associated with high pressure washing reduces the overall time a vehicle spends in the wash, leading to shorter wait times for customers.

high pressure water jet for car wash

Additionally, hydraulic ramps are known for their durability and stability. Made from high-quality materials, these ramps can support a significant amount of weight, ensuring that they are safe for regular use. Unlike conventional ramps, which might bend or buckle under pressure, hydraulic ramps provide a secure platform. This stability not only enhances safety but also encourages owners to wash their vehicles more frequently, helping to maintain the car's aesthetics and overall value over time.

car washing hydraulic ramp

Another important feature is the inclusion of various nozzle types. Most pressure washers come with interchangeable nozzles that allow you to switch between narrow and wide spray patterns. A wide-angle nozzle is perfect for rinsing large surfaces, while a narrow nozzle can help target tough spots. A foam cannon attachment is also a fantastic addition, as it allows you to apply soap evenly and generously over the vehicle surface, enhancing the cleaning process.

good pressure washer for washing cars

Moreover, car wash equipment has become increasingly environmentally conscious. Innovative manufacturers are developing systems that recycle water and minimize the use of harmful chemicals, aligning with global efforts towards sustainability. The introduction of biodegradable soaps and solutions further reflects a shift towards a more responsible approach to vehicle maintenance.

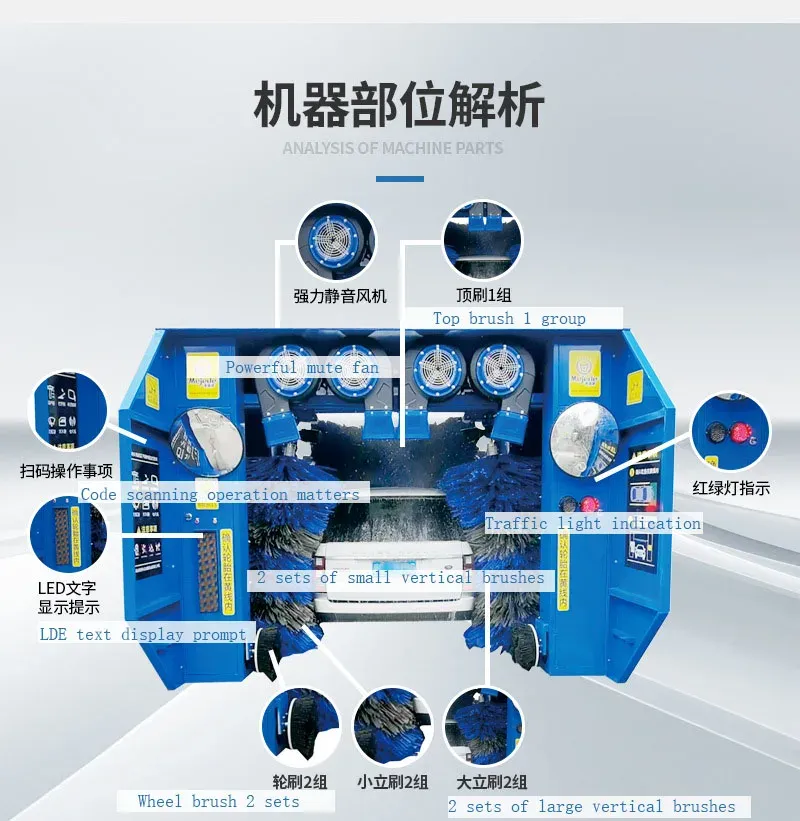

In recent years, the demand for automatic car wash services has surged, prompting many entrepreneurs to invest in automatic car wash equipment

. With this increased interest comes the critical question of pricing what should potential buyers expect regarding costs, and what factors influence these prices?One of the key benefits of automatic vehicle wash systems is their ability to deliver consistent results. Unlike manual washing, where the quality can vary based on the person performing the task, automatic systems provide a uniform wash every time. The machines are calibrated to optimize cleaning performance while being gentle enough to avoid damage to the vehicle's paint and finish. This reliability builds customer confidence and encourages repeat business.

automatic vehicle wash

In today's fast-paced world, maintaining the appearance and condition of our vehicles has become increasingly important. A clean and well-maintained car not only enhances its aesthetic appeal but also prolongs its lifespan. One innovation that has significantly changed the way we care for our vehicles is the car wash machine. These automated devices offer convenience, efficiency, and advanced cleaning technology, making them an integral part of modern vehicle maintenance.

The centrifugal slurry pump design plays a significant role in the effective transportation of slurry in mining operations. The design ensures that the pump can handle high-density materials without compromising performance. This is particularly important in mining, where the slurry often contains heavy and abrasive particles that can wear down pump components. The robust construction and optimized design of horizontal slurry pumps allow them to move large volumes of slurry over long distances, ensuring that materials are efficiently transported from extraction sites to processing facilities. By selecting the appropriate centrifugal pump for slurry, mining operations can maintain consistent material flow, reduce downtime, and enhance overall productivity.