Current location:Home > wash equipment >

wash equipment

2025-08-16 17:40

2025-08-16 17:33

2025-08-16 17:28

2025-08-16 17:08

2025-08-16 17:06

Express car wash systems are designed to optimize the washing process, ensuring that vehicles are cleaned thoroughly in a fraction of the time it used to take. Traditional car washes often involve multiple steps and can take anywhere from 20 minutes to an hour. In contrast, express car wash equipment streamlines this process, allowing cars to be cleaned in as little as 3 to 5 minutes. This is made possible through sophisticated machinery that employs advanced techniques, such as high-pressure water jets and automated brushes, to deliver exceptional results quickly.

...

2025-08-16 16:55

2025-08-16 16:14

2025-08-16 15:41

2025-08-16 15:29

2025-08-16 15:14

Latest articles

In today’s fast-paced world, convenience is key, and the need for efficient vehicle maintenance services has never been greater

. Among these services, car wash express tunnels have emerged as a game-changer, offering speed and thoroughness that traditional car washes struggle to match. This innovative approach not only saves time for busy individuals but also ensures that vehicles receive the care they deserve, keeping them clean and well-maintained.The material composition of the NU 316 bearing is another factor contributing to its durability and resilience nu 316 bearing. Typically made from high-quality steel, these bearings are often heat treated for increased hardness and resistance to wear and tear. Some manufacturers also incorporate anti-corrosion treatments, enhancing their performance in harsh environments.

nu 316 bearing. Typically made from high-quality steel, these bearings are often heat treated for increased hardness and resistance to wear and tear. Some manufacturers also incorporate anti-corrosion treatments, enhancing their performance in harsh environments.

nu 316 bearing. Typically made from high-quality steel, these bearings are often heat treated for increased hardness and resistance to wear and tear. Some manufacturers also incorporate anti-corrosion treatments, enhancing their performance in harsh environments.

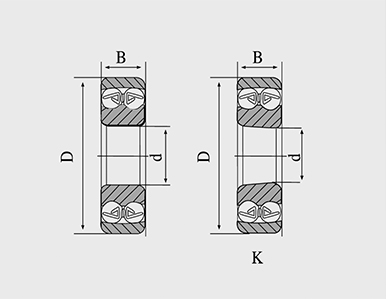

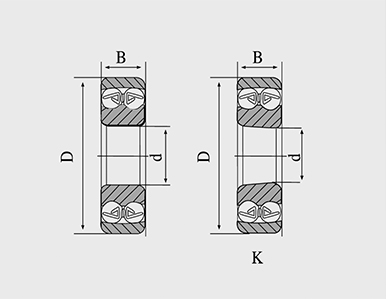

nu 316 bearing. Typically made from high-quality steel, these bearings are often heat treated for increased hardness and resistance to wear and tear. Some manufacturers also incorporate anti-corrosion treatments, enhancing their performance in harsh environments.Another advantage of NUP cylindrical roller bearings is their ability to accommodate misalignment. The loose rib on the outer ring allows the bearing to compensate for misalignment between the shaft and the housing, reducing the risk of premature failure due to misalignment The loose rib on the outer ring allows the bearing to compensate for misalignment between the shaft and the housing, reducing the risk of premature failure due to misalignment The loose rib on the outer ring allows the bearing to compensate for misalignment between the shaft and the housing, reducing the risk of premature failure due to misalignment The loose rib on the outer ring allows the bearing to compensate for misalignment between the shaft and the housing, reducing the risk of premature failure due to misalignment

The loose rib on the outer ring allows the bearing to compensate for misalignment between the shaft and the housing, reducing the risk of premature failure due to misalignment The loose rib on the outer ring allows the bearing to compensate for misalignment between the shaft and the housing, reducing the risk of premature failure due to misalignment nup cylindrical roller bearing. This makes NUP cylindrical roller bearings suitable for applications where shaft deflections or misalignments are common.

nup cylindrical roller bearing. This makes NUP cylindrical roller bearings suitable for applications where shaft deflections or misalignments are common.

The loose rib on the outer ring allows the bearing to compensate for misalignment between the shaft and the housing, reducing the risk of premature failure due to misalignment The loose rib on the outer ring allows the bearing to compensate for misalignment between the shaft and the housing, reducing the risk of premature failure due to misalignment

The loose rib on the outer ring allows the bearing to compensate for misalignment between the shaft and the housing, reducing the risk of premature failure due to misalignment The loose rib on the outer ring allows the bearing to compensate for misalignment between the shaft and the housing, reducing the risk of premature failure due to misalignment nup cylindrical roller bearing. This makes NUP cylindrical roller bearings suitable for applications where shaft deflections or misalignments are common.

nup cylindrical roller bearing. This makes NUP cylindrical roller bearings suitable for applications where shaft deflections or misalignments are common.