car wash pressure washer psi

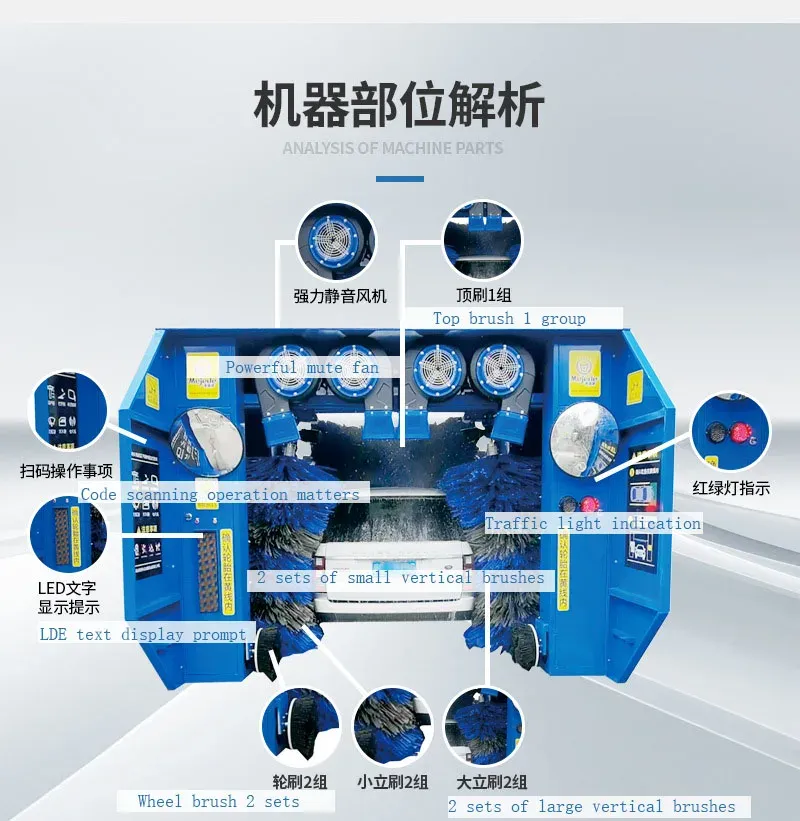

One of the main components of a tunnel washing system is its advanced spray technology, which utilizes high-pressure jets to remove dirt and contaminants from surfaces effectively

. This ensures that even hard-to-reach areas are thoroughly cleaned. Additionally, many systems incorporate brushes and foam applicators to further enhance cleaning efficacy, adapting to the specific needs of different materials and surfaces.tunnel washing system

Secondly, using a pressure washer can significantly reduce the amount of time spent on car detailing. In mere minutes, a detailer can rinse away layers of dirt and road salt that would otherwise take considerable scrubbing and multiple rinses to remove. Time is particularly valuable in a commercial detailing setup, where efficiency leads to more satisfied customers and higher turnover. The speed and thoroughness of pressure washing can make a detailing job look professional and polished without excessive effort.

car detailing pressure washers

Using the right cleaning solutions in conjunction with a pressure washer can also enhance the results

. Car-specific cleaning detergents are designed to work with pressure washers, helping to break down tough grime without harming the paint.Another important feature is the inclusion of various nozzle types. Most pressure washers come with interchangeable nozzles that allow you to switch between narrow and wide spray patterns. A wide-angle nozzle is perfect for rinsing large surfaces, while a narrow nozzle can help target tough spots. A foam cannon attachment is also a fantastic addition, as it allows you to apply soap evenly and generously over the vehicle surface, enhancing the cleaning process.

good pressure washer for washing cars

Another factor to consider is the material of the hose. Most pressure washer hoses are made from either rubber or PVC. Rubber hoses are more durable and can withstand higher temperatures, making them ideal for heavy-duty cleaning. On the other hand, PVC hoses are lighter and more flexible, which makes them easier to handle but may not be suitable for extreme conditions.

As industries grew, so did the need for more sophisticated factory buildings

. The addition of steam power and later electricity transformed the manufacturing process, allowing for more complex machinery and production lines. This technological advancement necessitated larger and more specialized spaces, leading to the development of multi-story factories. By the late 19th century, architects began incorporating elements of what would later be recognized as industrial design. Large windows were added to maximize natural light, while steel frame construction enabled larger, uninterrupted floor plans.