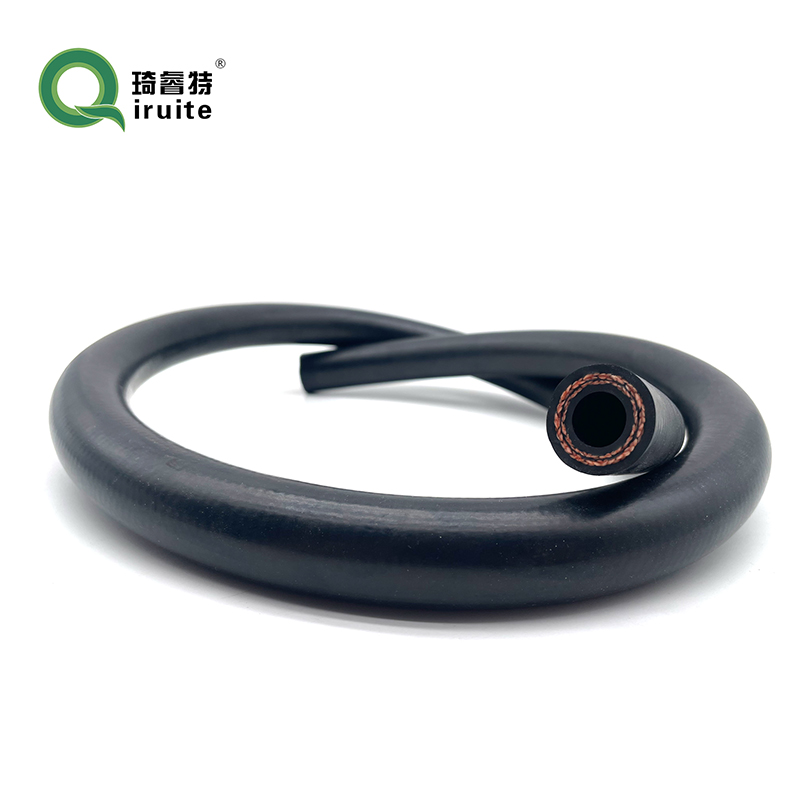

High-pressure washers are a cornerstone of self car wash equipment. These devices use powerful jets of water to remove dirt, grime, and even stubborn stains from the car’s surface. They are particularly effective for cleaning the undercarriage, wheels, and other hard-to-reach areas that often get neglected during routine washes. Additionally, many models come with adjustable pressure settings, allowing users to adjust the water pressure based on the surface being cleaned.

self car wash equipment