car wash jet wash equipment

One of the standout features of contemporary automated car wash equipment is its integration with smart technology. Many modern systems are equipped with sensors and cameras that enhance the cleaning process. These sensors can detect dirt levels and adjust water pressure accordingly, ensuring that each car receives a customized wash. Additionally, some systems utilize computer algorithms to optimize the sequence of cleaning actions, resulting in reduced water and energy consumption.

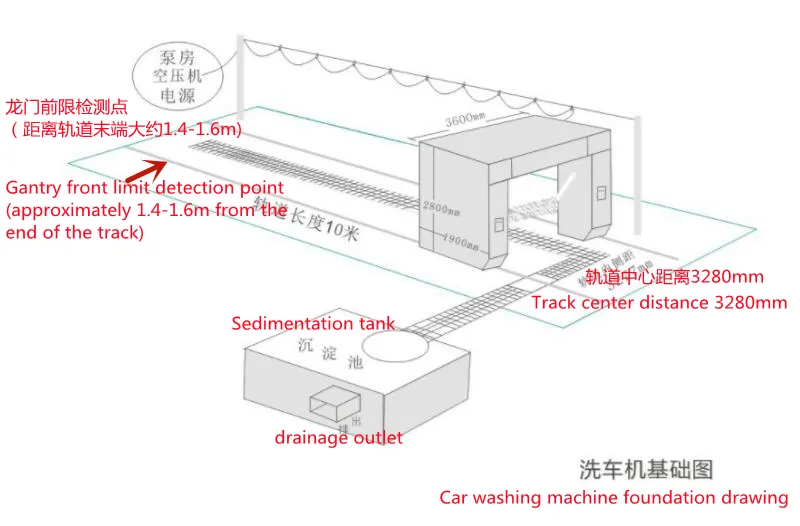

automated car wash equipment

The compact size of 12V car washing machines also makes them user-friendly. Typically lightweight and easy to maneuver, they can be stored in the trunk of a car, making them ideal for those who are always on the go. With the ever-growing trend of road trips and outdoor adventures, having a portable car washing solution readily available is an undeniable advantage. Whether you’re dealing with mud from a camping trip or salt from winter roads, a quick wash is just a plug away.

car washing machine 12v

For commercial purposes, car washing equipment can be significantly more expensive. Automatic car wash systems, for instance, can cost anywhere from $15,000 to upwards of $100,000, depending on the technology and capabilities. These systems often feature advanced technology, like touchless washing or foam application, and can wash multiple vehicles in a short time, making them ideal for businesses looking to maximize efficiency and throughput.

car washing equipment price

Isaalang-alang din ang mga gastos sa operasyon at maintenance. Bukod sa paunang halaga ng makina, kinakailangan ding isaalang-alang ang mga gastos sa kuryente, tubig, at mga cleaning supplies. Ang mga commercial-grade na makina, kahit na mahal, ay madalas na mas matibay at mas nakakatipid sa tubig at kuryente. Kung ikaw ay nagtatayo ng negosyo sa paglilinis ng sasakyan, ang mga ito ay malaking tulong upang mapanatili ang iyong mga gastos sa pangmatagalang panahon.

price of a car wash machine

In agriculture, propeller pumps are commonly employed for irrigation purposes. With the ever-increasing need for food production and sustainable practices, farmers often rely on these pumps to distribute water from reservoirs or rivers to their fields. The efficiency and reliability of propeller pumps allow for optimal irrigation strategies, which are vital in maintaining crop health and maximizing yield. Moreover, they can operate in varying conditions, making them suitable for diverse agricultural environments.

propeller pump is used for