pressure motor for car wash

One of the most notable innovations in auto car wash equipment is the introduction of touchless car washes. Utilizing high-pressure water jets and specialized cleaning agents, these systems meticulously clean vehicles without any physical contact. This reduces the risk of scratches and swirl marks that can occur with traditional brushes. Touchless systems are particularly appealing to vehicle owners who prioritize maintaining their car's exterior in pristine condition.

Heavy-duty car washers are built to last. Crafted from robust materials that can withstand the rigors of regular use, these washers often come with warranties that reflect their durability. Investing in a heavy-duty model means that you are less likely to encounter issues such as leaks or mechanical failures, which can be common in lighter models. The long lifespan of heavy-duty car washers makes them a cost-effective choice in the long run, as they require fewer repairs and replacements.

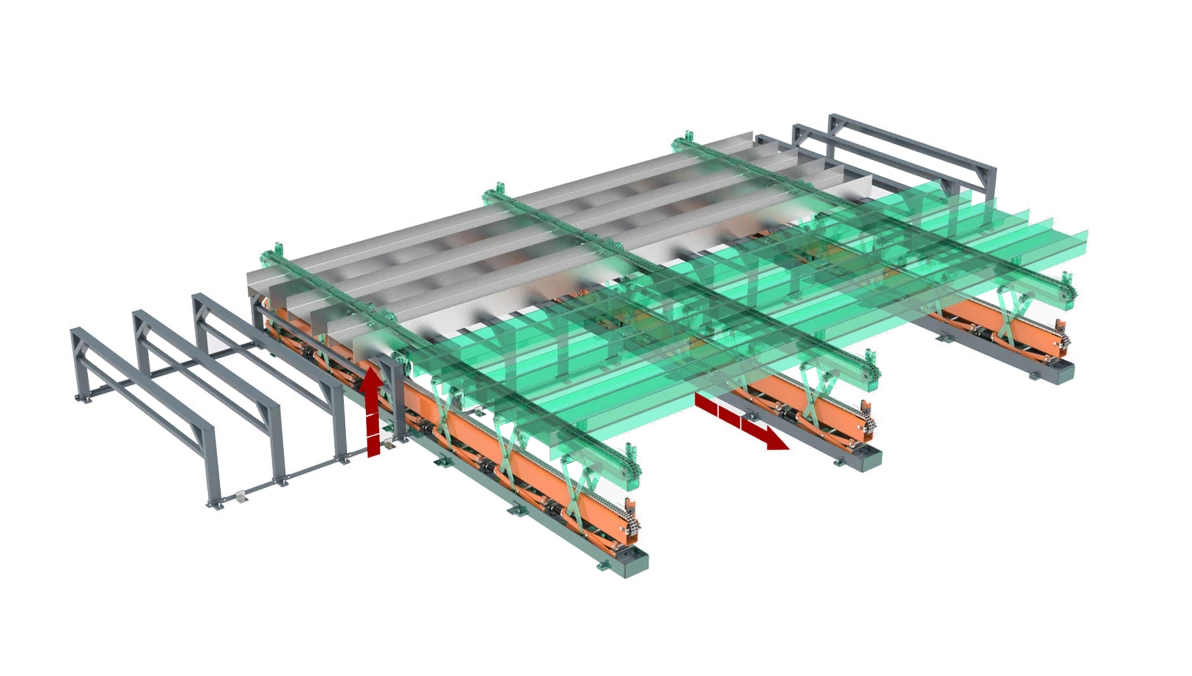

car washer heavy duty

One of the key advantages of using a car cleaning washer is its efficiency. Time is a precious commodity, and with a washer, you can significantly reduce the amount of time spent washing your vehicle. Typically, a professional wash can take anywhere from 30 minutes to an hour. However, with a car cleaning washer, the process can be completed in a matter of minutes, allowing you to dedicate more time to other important tasks.

car cleaning washer

Moreover, the integration of environmentally-friendly technologies into industrial car cleaning equipment has become a significant trend. Many manufacturers are now focusing on creating machines that utilize less water and biodegradable cleaning agents. This not only helps in reducing the environmental footprint of car cleaning services but also appeals to eco-conscious consumers who prefer to support businesses that prioritize sustainability.

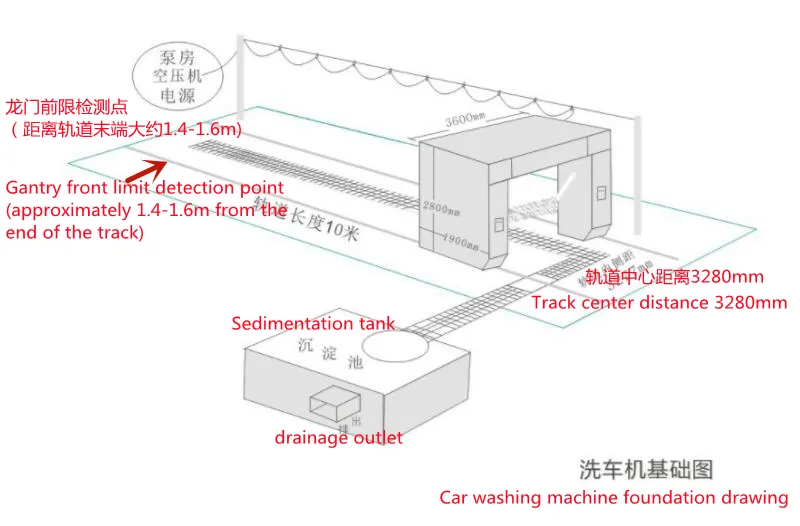

industrial car cleaning equipment

Automated spray coating systems have revolutionized industries that require precision and consistency in coating applications

. These advancements go beyond the capabilities of traditional manual methods and offer unmatched efficiency and reliability in achieving desired specifications. Developed through extensive engineering research and decades of expertise in material science, these systems are now indispensable tools in sectors such as automotive, aerospace, and consumer electronics.

Navigating the world of automatic paint spraying equipment unveils a delicate balance between technology

, precision, and artistry. In today's rapidly evolving manufacturing landscape, the demand for higher efficiency, consistent quality, and enhanced scalability has exponentially increased the reliance on this equipment. As industries across the globe increasingly seek automation, understanding the nuances of automatic paint systems has become imperative for anyone looking to optimize production lines and maintain a competitive edge.