types of car wash machines

One of the key benefits of soft spray car washes is their ability to cleanse thoroughly while minimizing the risk of damage. The soft wash process gently dislodges dirt and debris from the vehicle’s exterior, including hard-to-reach areas such as rims and undercarriages. This level of detail ensures that the car not only looks clean but maintains its protective coatings and overall finish.

One of the main considerations when selecting a pressure washer hose is its compatibility with your machine. Pressure washer hoses come in various lengths, typically ranging from 25 to 100 feet. A longer hose allows you to reach different areas of your vehicle without having to move the washer frequently, making the cleaning process more efficient. However, it’s essential to balance length with the potential for pressure loss over longer distances; therefore, choosing the appropriate length for your washing needs is key.

One of the standout features of high-pressure washing machines is their ability to reach difficult areas of a vehicle that are often neglected during traditional washing methods. Components such as wheel wells, undercarriages, and intricate body designs can accumulate dirt and contaminants that are hard to access. The focused jets of water from high-pressure washers can penetrate these tight spaces, ensuring a comprehensive clean that promotes not only aesthetics but also the longevity of vehicle parts.

A gas pressure washer operates by utilizing a gasoline engine to power a high-pressure water pump. This combination produces a much higher flow and pressure than electric models, making it particularly suitable for automotive detailing. With pressure ratings often exceeding 3000 PSI (pounds per square inch), these machines can easily blast away dirt, grime, and stubborn stains from various surfaces of your car.

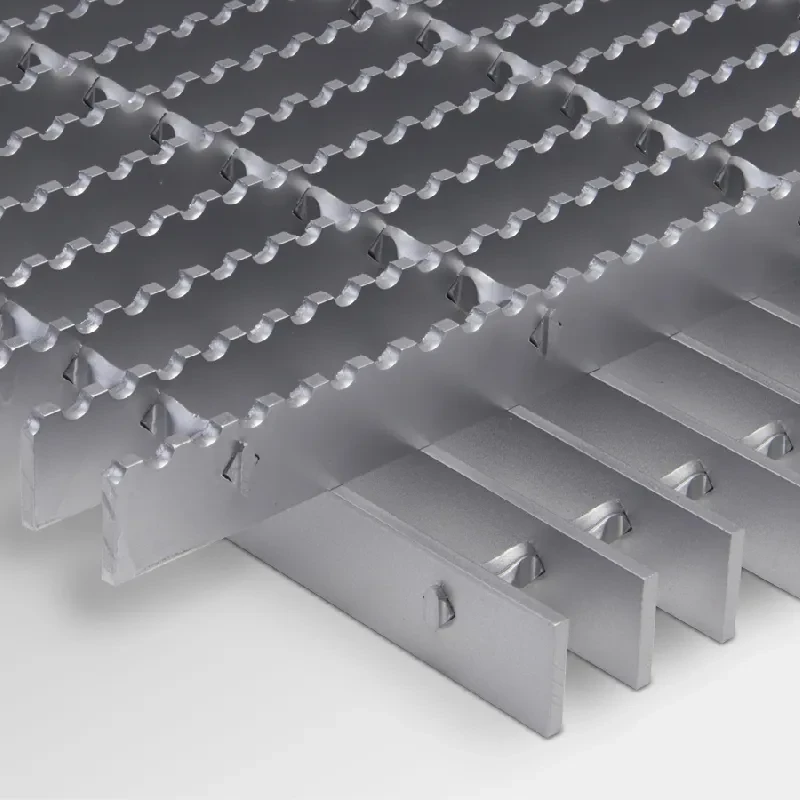

Kolejnym ważnym aspektem specyfikacji aluminiowych krat jest ich konstrukcja. Istnieje wiele różnych typów krat, w tym kratki pełne, lekkie i kompozytowe. Każdy typ ma swoje unikalne zastosowanie. Na przykład, kratki pełne są idealne do zastosowań przemysłowych, gdzie wymagana jest większa nośność i stabilność, podczas gdy lekkie kratki mogą być wykorzystywane w obiektach o mniejszym obciążeniu.