vehicle wash systems

Moreover, understanding the correct order of operations is essential. Wheels, being the dirtiest part of a car, should be cleaned first to avoid redepositing grime onto the painted surfaces. Afterward, a thorough wash of the body using microfiber cloths prevents scratches and provides a streak-free finish. Finally, applying wax not only protects the paint but also enhances the car's shine, giving it that showroom-ready look.

professional car washer

Before starting, it's essential to prepare your car for washing. Begin by rinsing the vehicle with water, which helps remove loose dirt and prevents scratches during the washing process. Once your car is rinsed, use a pressure washer with the recommended PSI to apply soap. Always use a soap designed specifically for use with pressure washers, as household detergents can contain harsh chemicals that might harm your vehicle's finish.

psi for pressure washer car

One of the primary advantages of self-service car wash machines is their affordability. Traditional car wash services can be quite costly, especially for regular users. By investing in a self-service wash, car owners can save money in the long run, as they only pay for the time and services they use. Many machines offer a coin-operated system or digital payment options, making them accessible and easy to use.

self service car wash machine for sale

One of the most pressing concerns regarding the price of diesel is how it directly affects maintenance and operational costs. For businesses that rely on steamers for daily operations, the increased cost of diesel means higher expenditures. Many operators have been forced to rethink their budgets and find ways to cut costs without sacrificing quality. This may include optimizing their usage of steamers, training personnel to maximize efficiency, or even investing in alternative fuel sources that can minimize reliance on diesel.

optima steamer diesel price

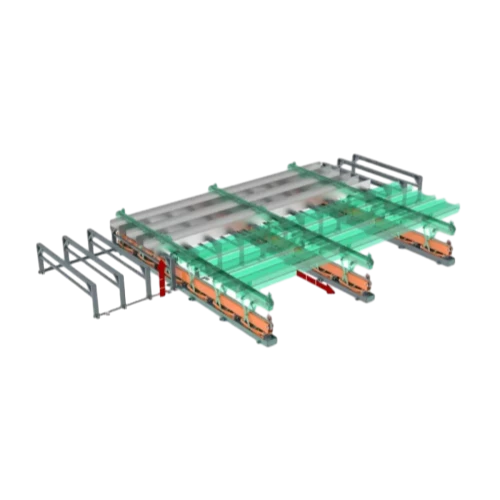

The adoption of robotic welders is quickly becoming a trend across various industries, particularly in advanced fabrication. These machines are designed to handle complex welding tasks with high accuracy, making them ideal for industries like automotive, aerospace, and heavy machinery. As companies look to streamline operations, welding arms equipped with automation capabilities offer a perfect solution for tackling projects that require tight tolerances and consistency.